Menu

We were contracted by a subsea operator to work on a deck spread design, engineering, fabrication and installation project, in support of its upcoming P&A campaign. We were asked to manage:

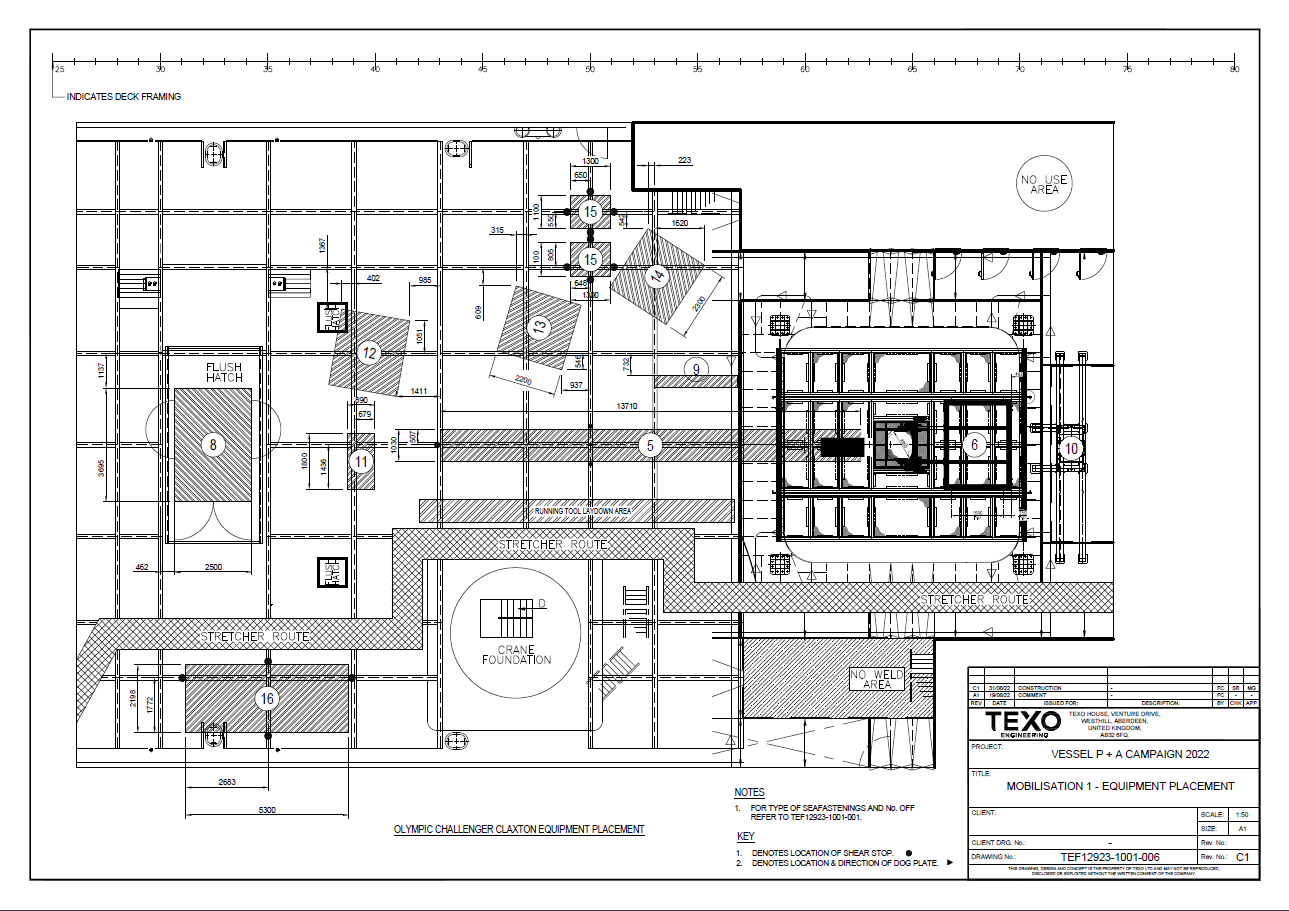

• Vessel deck planning and equipment layout design

• Equipment grillage and seafastening engineering and design

• Equipment grillage and seafastening fabrication

• Vessel mobilisation – grillage, equipment and seafastening installation

We were chosen for this project because we can provide a full turnkey solution on projects of this type. Our approach helps customers to reduce bottlenecks, minimise risks and benefit from the simplicity of dealing with one supplier.

We worked closely with the customer to manage very specific equipment requirements up until the vessel’s departure, having an engineer onsite allowed calculations being updated live as mobilisation was in progress. It was important to plan with crew safety at the top of the agenda.

Within the restrictions of very limited space on the vessel deck, we were able to manage all the equipment requirements whilst maintaining a safe working layout. The client was delighted with our approach to this project and the results we achieved.