Offshore Accommodation

Orbital Marine Power

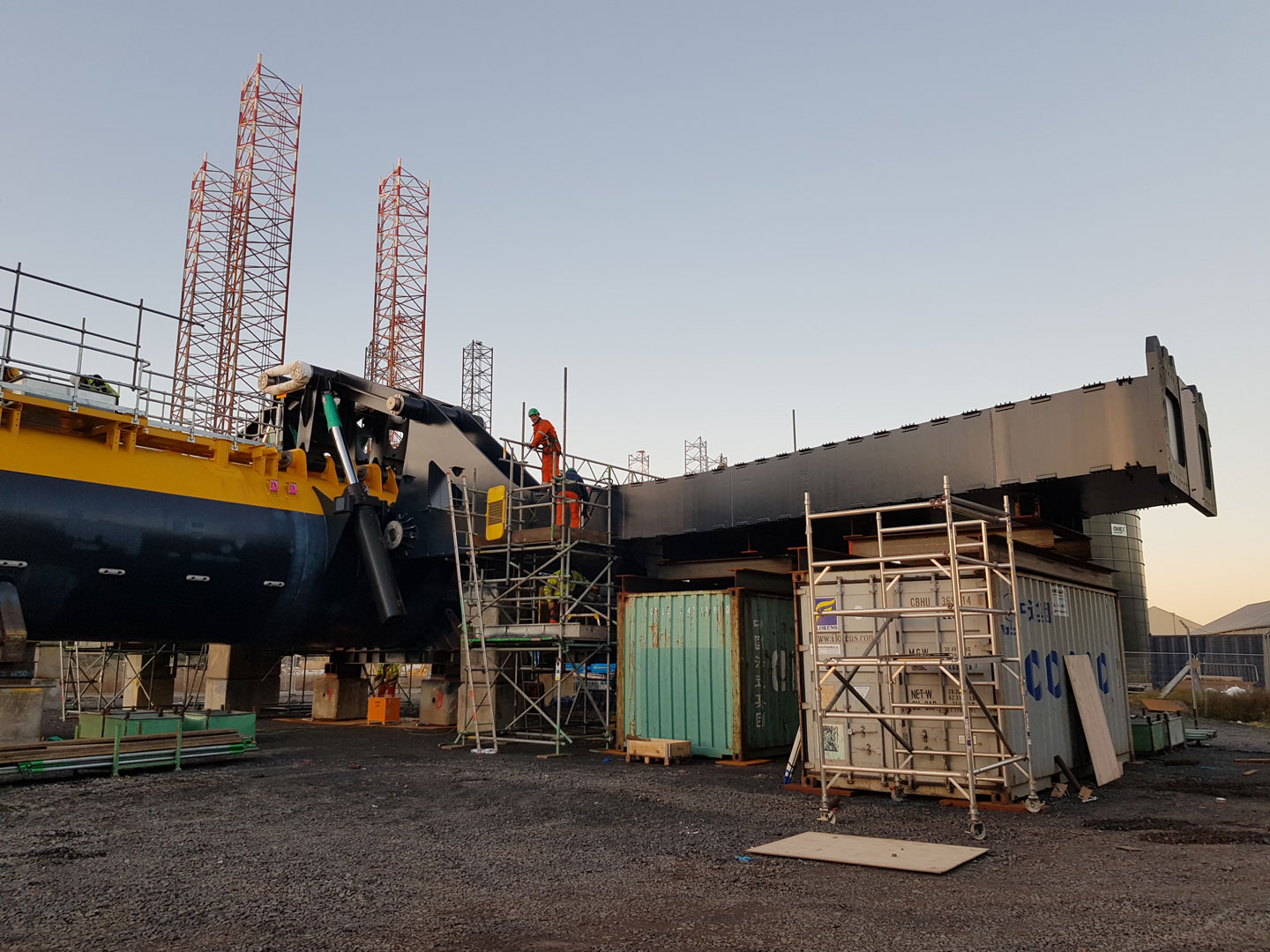

TEXO Engineering and Fabrication was awarded the project to construct the commercial O2 tidal turbine, the most powerful tidal turbine in the world. The O2 is a 72m long floating superstructure, supporting two 1 MW turbines at either side for a nameplate power output of 2MW, at a tidal current speed of 2.5 m/s. With rotor diameters of 20m, it has a 600sq metre rotor area, the largest ever on a single tidal generating platform to date.

The solution

We fabricated the turbine at our Port of Dundee quayside facility, which was enlarged during the project. After initial fabrication indoors, the turbine was moved onto the quayside for the addition of legs, forward and aft hull sections and sails. The turbine then underwent land testing before being towed to its final position off the coast of the Orkney Islands.

The result

One of the most complicated parts of the overall assembly phase was the complex operation of assembling each set of three large linkages, with connecting pins weighing up to 2 Te. Together with the main hydraulic rams, these complete assemblies weighed in at 18 Te each.

Once assembled, the linkages were lifted and manoeuvred so that they could be attached to the main hull structure and the leg tops. This involved horizontally jacking-in large machined pins to the line-bored clevises on the hull and leg sections.

The drawing of the operation and lift sequences was carefully prepared on CAD by TEXO Engineering and sequenced in a “story-board” to plan out the safe execution of this complex lifting operation. Both the port and starboard linkage and ram assemblies were successfully installed over two days, using twin 25T overhead cranes in the main fabrication shed.

Testimonial

“The O2 programme has given us a significant opportunity to demonstrate our multi-disciplinary capabilities, and our proactive approach to working collaboratively with clients. We firmly believe that the transition to a net zero environment will deliver a range of opportunities to the UK’s engineering and fabrication sectors and we are very proud to see the launch of Orbital’s O2 turbine.”

Chris Smith, Managing Director of TEXO Group

“The O2 programme has given us a significant opportunity to demonstrate our multi-disciplinary capabilities, and our proactive approach to working collaboratively with clients. We firmly believe that the transition to a net zero environment will deliver a range of opportunities to the UK’s engineering and fabrication sectors and we are very proud to see the launch of Orbital’s O2 turbine.”

Chris Smith, Managing Director of TEXO Group

Testimonial

The delivery of our flagship O2 turbine represented a complex, first-of-kind, fabrication, assembly and launch contract and the service we got from TEXO Fabrication, along with support from the wider TEXO Group, throughout the delivery of this high-profile project from their Dundee facility was outstanding. The team at TEXO were accommodating, professional and committed to executing the project safely and to budget and specification – exactly what we were wanting to find in a supply chain partner.

Andrew Scott, CEO, Orbital Marine Power, Ltd.

The delivery of our flagship O2 turbine represented a complex, first-of-kind, fabrication, assembly and launch contract and the service we got from TEXO Fabrication, along with support from the wider TEXO Group, throughout the delivery of this high-profile project from their Dundee facility was outstanding. The team at TEXO were accommodating, professional and committed to executing the project safely and to budget and specification – exactly what we were wanting to find in a supply chain partner.

Andrew Scott, CEO, Orbital Marine Power, Ltd.